Features of WPGR series straight planetary reducer

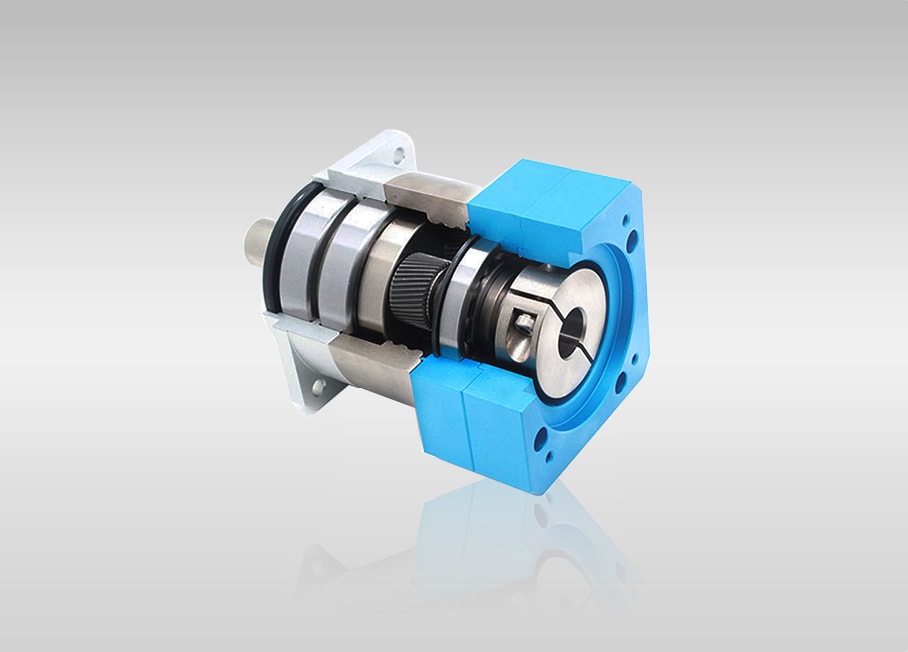

1. The external gearbox is made of high-quality 20CrMnT/20CrMo/SCM415 material, controlled carburizing and quenching.

Its surface hardness is as high as HRC60±2; the gear surface fine rolling/grinding precision is JIS2 level;

It has features such as stable operation, low noise, high load torque and low backlash;

2. The internal gearbox are processed by multiple broaching or spiral cutting methods commonly used in Japan and Taiwan, China;

3. When the planetary gearbox set is running, it will be in a state of complete tight meshing, which reduces the situation of gearbox damage caused by gearbox collision or partial meshing.

The characteristics of complete tight meshing make the efficiency loss of each gearbox transmission only 3%.

This type of transmission can ensure high transmission efficiency when the kinetic energy is input into the reducer and then to the mechanical end, and avoid friction caused by internal gearbox, sliding, resulting in mechanical loss;

4. The modular design of the input shaft of the reducer is suitable for any manufacturer and any type of motor;

The rear transition flange of the reducer is made of magnesium-aluminum alloy material, which has a beautiful appearance, light weight and good heat dissipation after surface treatment;

5. All reducer models are equipped with skeleton oil seals to prevent oil leakage during high-speed operation of the reducer;

Standard parts such as bearings and oil seals adopt international and domestic famous brand products;

6. The shaft is made of alloy steel and quenched and tempered to meet requirements of strength and toughness.

Drawings of WPGR series straight planetary reducer

Parameters of WPGR series straight planetary reducer

| Size | WPGR060 | WPGR070 | WPGR080 | WPGR090 | WPGR115 | WPGR142 | WPGR215 | |

|---|---|---|---|---|---|---|---|---|

| D1 | 70 | 85 | 90 | 100 | 130 | 185 | 235 | |

| D2 | 5.5 | 5.5 | 6.5 | 6.5 | 9 | 11 | 13.5 | |

| D3h6 | 14 | 16 | 20 | 22 | 25 | 40 | 55 | |

| D4g6 | 50 | 50 | 70 | 80 | 110 | 130 | 180 | |

| D5 | 17 | 20 | 25 | 30 | 40 | 60 | 65 | |

| D6 | M5X0.8P | M5X0.8P | M6X1P | M8X1.25P | M10X1.5P | M12X1.75P | M20X2.5P | |

| D10 | 60 | 70 | 80 | 90 | 120 | 142 | 205 | |

| L1 | 60 | 75 | 90 | 90 | 120 | 142 | 215 | |

| L2 | 32 | 35 | 40 | 40 | 55 | 85 | 90 | |

| L3 | 3 | 5 | 3 | 3 | 4 | 5 | 6 | |

| L4 | 10 | 10 | 10 | 10 | 15 | 15 | 20 | |

| L5 | 28 | 28 | 36 | 36 | 50 | 80 | 82 | |

| L6 | 2 | 3 | 3 | 3 | 5 | 6 | 7.5 | |

| L7 | 25 | 25 | 30 | 30 | 40 | 55 | 70 | |

| L8 | 1 | 1 | 1 | 1 | 3 | 4 | 4 | |

| L9 | 10 | 10 | 12 | 12 | 23 | 30 | 30 | |

| C1* | 70 | 70 | 90 | 90 | 145 | 200 | 200 | |

| C2* | M5X0.8P | M5X0.8P | M6X1P | M6X1P | 8X1.25P | M12X1.75P | M12X1.75P | |

| C3* | 14 | 14 | 19≤C3≤22 | 19≤C3≤22 | 19≤C3≤24 | 22≤C3≤42 | 22≤C3≤42 | |

| C4* | 33 | 33 | 41 | 41 | 60 | 82.5 | 82.5 | |

| C5* | 50 | 50 | 70 | 70 | 110 | 114.3 | 114.3 | |

| C6* | 4 | 4 | 7 | 7 | 30 | 30 | 30 | |

| C7* | 60 | 60 | 90 | 90 | 130 | 180 | 180 | |

| C9* | 67 | 67 | __ | 98 | 132 | __ | __ | |

| C10* | 97 | 97 | __ | 143 | 192 | __ | __ | |

| B1 | 5 | 5 | 6 | 6 | 8 | 42 | 16 | |

| H1 | 16 | 18 | 22.5 | 24.5 | 28 | 43 | 59 | |

| C8* | L1 | 135 | 141.5 | __ | 198 | 266 | __ | __ |

| L2 | 151.5 | 167 | __ | 223 | 298 | __ | __ | |

| Size | Stage | Ratios | WPGR060 | WPGR070 | WPGR080 | WPGR090 | WPGR115 | WPGR142 | WPGR215 |

|---|---|---|---|---|---|---|---|---|---|

| Rated output torque(Nm) |

L1 | 3 | 18 | 22 | 40 | 75 | 120 | 400 | 1050 |

| 4 | 40 | 45 | 110 | 85 | 215 | 800 | 1780 | ||

| 5 | 36 | 41 | 90 | 100 | 230 | 700 | 1600 | ||

| 7 | 25 | 26 | 50 | 80 | 160 | 550 | 1000 | ||

| 10 | 15 | 15 | 22 | 50 | 110 | 210 | 305 | ||

| L2 | 12 | 20 | 45 | 110 | 75 | 120 | 800 | 1780 | |

| 15 | 20 | 41 | 90 | 75 | 120 | 700 | 1600 | ||

| 20 | 31 | 45 | 110 | 85 | 215 | 800 | 1000 | ||

| 25 | 39 | 41 | 90 | 100 | 230 | 700 | 1780 | ||

| 30 | 20 | 41 | 90 | 75 | 120 | 700 | 1600 | ||

| 35 | 39 | - | 55 | 100 | 230 | 550 | 1600 | ||

| 40 | 31 | 41 | 90 | 85 | 215 | 700 | 1600 | ||

| 50 | 39 | 25 | 50 | 100 | 230 | 450 | 700 | ||

| 70 | 25 | — | — | 80 | 160 | - | - | ||

| 100 | 15 | 40 | 110 | 50 | 110 | 800 | 1780 | ||

| Max instantaneous output torque(N.m) | L1,L2 | 3~100 | 2.0 times Rated output torque | ||||||

| Return backlash(arcmin) | L1 | 3~10 | ≤12 | ≤12 | ≤12 | ≤12 | ≤12 | ≤12 | ≤12 |

| L2 | 12~100 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | |

| Rated input speed(rpm) | L1,L2 | 3~100 | 4000 | 4000 | 3500 | 3500 | 3500 | 3000 | 2500 |

| Max input speed(rpm) | L1,L2 | 3~100 | 8000 | 8000 | 6000 | 6000 | 6000 | 4500 | 4000 |

| Torsional stiffness(Nm/arcmin) | L1,L2 | 3~100 | 1.8 | 1.95 | 4.7 | 4.85 | 11 | 35 | 55 |

| Allowable Radial Load(N) | L1,L2 | 3~100 | 240 | 265 | 400 | 450 | 120 | 3700 | 4800 |

| Allowable axial load(N) | L1,L2 | 3~100 | 220 | 230 | 420 | 430 | 1000 | 3500 | 4500 |

| Noise(dB/1m) | L1,L2 | 3~100 | 56 | 58 | 60 | 63 | 68 | 70 | 70 |

| Life(hrs) | L1,L2 | 3~100 | 20,000 | ||||||

| Efficiency at full load(%) | L1 | 3~10 | ≥97% | ||||||

| L2 | 12~100 | ≥94% | |||||||

| Temperature(°C) | L1,L2 | 3~10 | -10℃~+90℃ | ||||||

| Degree of protection | L1,L2 | 3~100 | IP65 | ||||||

| Grease | L1,L2 | 3~100 | Fully Synthetic Grease | ||||||

| Transmission inertia of reducer | |||||||||

| Size | Stage | Ratios | WPGR060 | WPGR070 | WPGR080 | WPGR090 | WPGR115 | WPGR142 | WPGR215 |

| Moment of inertia(kg.cm) | L1 | 3 | 0.135 | 0.135 | 0.77 | 0.77 | 2.63 | 5.83 | 251.6 |

| 4 | 0.093 | 0.093 | 0.52 | 0.52 | 1.79 | 3.21 | 243 | ||

| 5 | 0.078 | 0.078 | 0.45 | 0.45 | 1.53 | 3.1 | 232.8 | ||

| 7 | 0.065 | 0.065 | 0.39 | 0.39 | 1.3 | 2.1 | 205.8 | ||

| 10 | 0.063 | 0.063 | 0.39 | 0.39 | 1.28 | 1.95 | |||

| L2 | 12 | 0.11 | - | 0.37 | 0.37 | 3.27 | - | ||

| 15 | 0.039 | 0.039 | 0.72 | 0.72 | 2.4 | 3.35 | 55.3 | ||

| 20 | 0.049 | 0.049 | 0.35 | 0.35 | 1.06 | 2.73 | 52.1 | ||

| 25 | 0.039 | 0.039 | 0.25 | 0.25 | 1.4 | 2.25 | 50.09 | ||

| 30 | 0.038 | 0.038 | 0.18 | 0.18 | 1.4 | 2.25 | 50.09 | ||

| 35 | 0.09 | - | 0.35 | 0.35 | - | - | - | ||

| 40 | 0.27 | 0.027 | 0.18 | 0.18 | 1.3 | 2.25 | - | ||

| 50 | 0.09 | - | 0.35 | 0.35 | 3.04 | - | - | ||

| 70 | 0.09 | - | 0.35 | 0.35 | 3.04 | - | - | ||

| 100 | 0.016 | 0.016 | 0.25 | 0.25 | 1.35 | 2.15 | - | ||

Factories of Fubao Mechanic Tech

Quote Now